SFB Subproject SP9 (2024 – 2028): Material- and Structurally Informed Freeform Structures

Subproject Leader

Milena Stavrić

Projekt Members

Julian Jauk

Lukas Gosch

Cornelia Ott

Student Project Assistent

Britta Nader

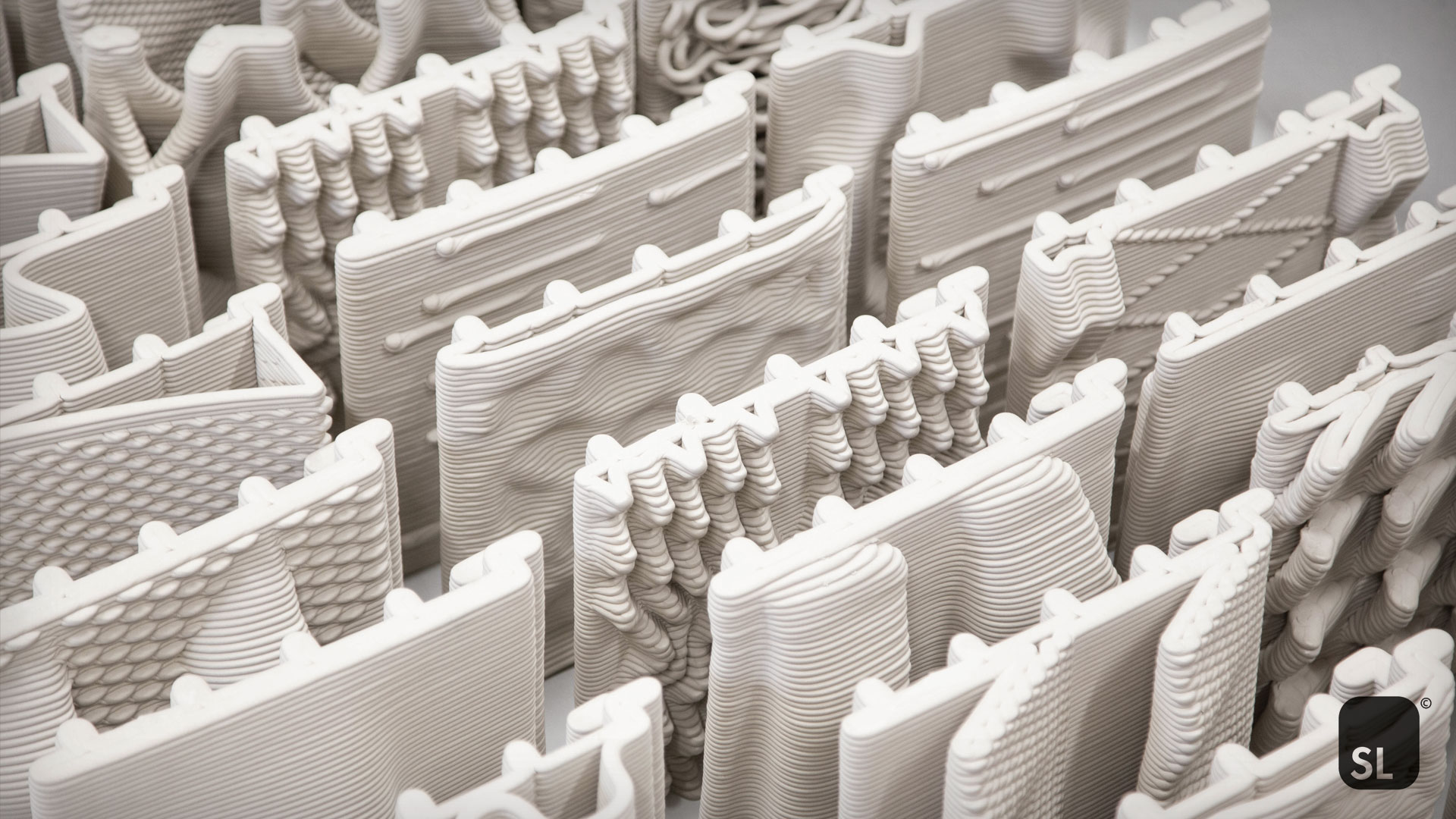

Motivation/long term goals: Despite the possibility to generate, discretise and present freeform surfaces (also called freeforms) by appropriate computer software, materialisation and simulation are still a big challenge. The limited knowledge regarding the complex relationship between mechanical properties, geometry, thermal properties, acoustic behaviour and size of architectural elements significantly restricts the effective utilization of traditional building materials in freeform architectural design. Currently, such designs are materialised in concrete or glass, whose production additionally burdens our environment. One of the main future questions is how we can combine traditional materials with digital toolsets in a sustainable way. The current inadequacy of conventional fabrication strategies further restricts adoption of digitally fabricated elements.

First funding period: Experimental ways of generating freeform surfaces were developed based on their material and functional properties with a particular focus on the development of cost-efficient and/or stay-in-place/reusable structures. Such materials and models provide basic knowledge for the enrichment of geometrical and material-informed computational design of freeform self-supporting structures.

Second funding period: Based on the results of the first phase, we will further investigate the relationship between material, geometry, size of the building elements and the appropriate fabrication strategy for different clay-based composites. The contribution will take place in three phases: 1) expansion and preparation of the toolset for multi-material gradient extrusion for a standard clay printer, a 6-axis robotic arm, and a clay 3D printer for fabricating objects on an architectural scale; 2) experimentation with different clay-based composites for different scales and set-up of a new workflow based on the new toolset; 3) upscaling the developed processes by realization of architectural mock-ups on a large scale, such as pavilion-like ”walk-in” architecture.